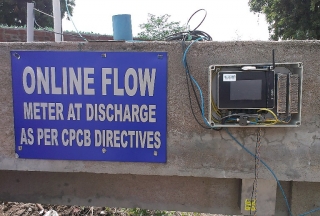

The Indian Central Pollution Control Board (CPCB) has issued directions for 17 highly polluting industries such as Pulp & Paper plants, Tanneries or Oil Refineries in order to increase the water quality of the river Ganga and its tributaries.

India is monitoring industrial discharges in real time

Details

All of these industries that have been discharging effluent directly or indirectly into the river Ganga are required to install online effluent quality and common emission monitoring systems to help track the discharges of pollutants from these units. Measurement results have to be transmitted to CPCB on continuous basis. The parameters that must be monitored include pH, COD, BOD, TSS and other sector specific parameters. UV Vis spectrometry has been approved by the Indian authorities as a reliable method for testing BOD and COD. It is suitable for complex and fluctuating matrices.

Banthar Unnao Tannery

At the wastewater treatment plant of a leather tannery in Banthar Unnao, India a s::can system has been installed to monitor influent and effluent by our partner Aaxis Nano Technologies.

A spectro::lyser™ along with a pH::lyser and a con::cube terminal are ideally suited to fulfill the requirements specified in the CPCB guideline.

Because of its complex matrix the wastewater of the tanner´s mill cannot be monitored online by simple spectrophotometer probes which measure only single wave lengths. Information about the complete spectrum is needed for reliable online monitoring. As the graph below shows, the measurements of the spectro::lyser show a good fit to the reference data from the laboratory.