s::can’s spectro::lyser industrial monitors the effluent waste water quality for a well-known brewery in Vancouver, Canada. This allows the utility to catch product loss, save costs and meet regulator requirements.

Brewery saves costs and meets regulator requirements with s::can

Background

Background

A Vancouver, Canada based brewery has an ongoing requirement to monitor effluent wastewater parameters in their sump pit prior to discharge to Metro Vancouver. In the past they had issues with not meeting their industrial sewer permit requirements and needed a method of monitoring key parameter including COD, pH and TSS. Composite samples were sent out on a daily basis to an accredited lab. The sampling regime did not allow them to capture the ongoing events. The ongoing cost and the delay in receiving results presented an issue.

Challenges

Many challenges were encountert at this installation. The waste water was high in solids due to the use of diatomaceous earth in the process. The temperature and pH of the water changed radically during a week as part of the CIP cleaning process. The waste water was high in dissolved iron which can cause fouling with compressed air cleaning.

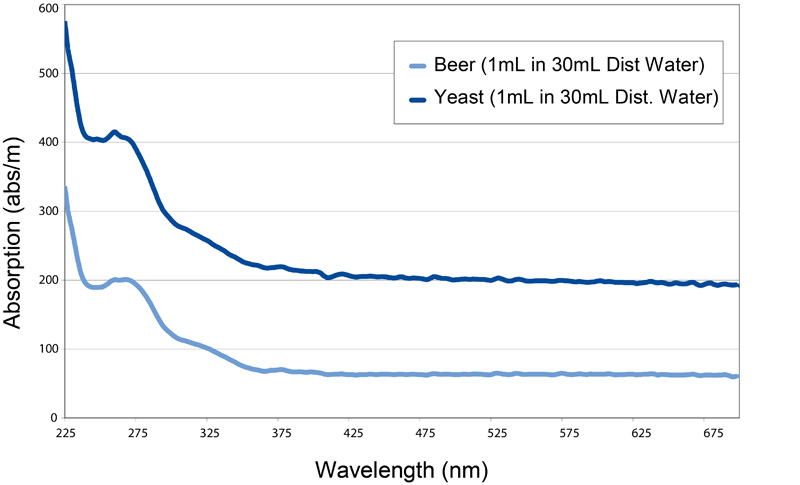

Absorption spectra of beer and yeast in distilled water. The absorbance signal observed was sufficiently strong and specific for the detection and quantification in the waste water matrix.

Solution

s::can’s sales partner Aquatic Life was approached about a solution for an ongoing requirement in monitoring waste water quality. The installation included a con::stat terminal with a global calibration for brewery, ana::pro software, spectro::lyser industrial spectrometer probe and a pH::lyser pro sensor. s::can prepared a special calibration accurately interpreting the spectral data, which proved to be very successful.

Benefits

The system provides ongoing 24-hour monitoring from which the client for example was able to see a 80 000 L of beer discharge which occurred over a ½-hour period. This would not have been caught with a 24-hour composite sample. The cost savings through the reduction of the number of lab samples required is also a big advantage. In addition, the system gives insights into the overall operation especially at night. The client is able to adjust processes to ensure that it meets permit obligations.