A s::can system at a waste water treatment plant in El Gouna, Egypt is used to enable modeling and dynamic simulation of different biological processes. With the help of the results, innovative solutions allowing capacity increases of existing WWTPs can be evaluated.

Optimization of different biofilm reactors for waste water treatment in warm climates

Background

Background – Comparison of activated sludge, fixed and moving bed biofilm carrier hybrid process

The waste water of the growing tourist city El Gouna in Egypt is treated in a central activated sludge wastewater treatment plant. Despite the city’s growth and therefore increase in inflow to the WWTP-site, new constructions are not allowed.

Carsten Riechelmann currently works for the Water Engineering Department at Campus El Gouna of the Technical University Berlin to support the city services through a real scale test of different options to increase the WWTP’s capacity. Together with Tristan Wilms he is analyzing whether or not techniques that proved applicable in <15°C bioreactors in Europe are also beneficial in >30°C warm Egyptian WWTPs.

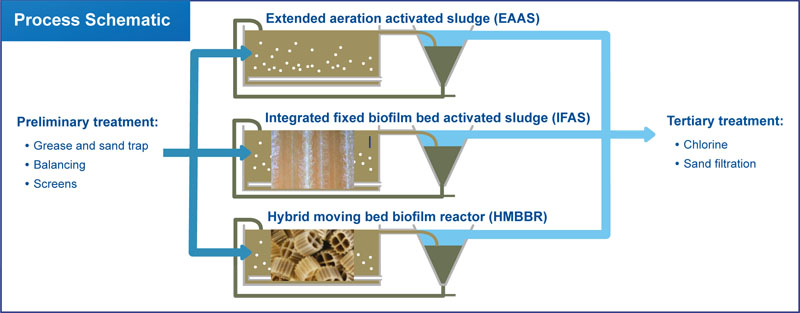

Riechelmann is running a comparison between three techniques: an optimization of the conventional activated sludge process, the application of a fixed and also a moving bed biofilm carrier hybrid process. The application of biofilm carriers is an innovative solution because they allow the upgrading of existing WWTPs without building new tanks. However, since it is a relatively new procedure compared to conventional activated sludge systems, there are some uncertainties in their design, transormation processes and performance.

s::can’s solution – Measuring COD, TSS, NO3, NH4, pH, O2 and temperature

To actually increase the treatment capacity regarding COD removal and nitrification, it is necessary to understand the influence of different parameters in the biological cleaning process. Using a self-developed sampling system together with the s::can Online Monitoring System, four different sample points are measured.

A spectro::lyser, an ammo::lyser and an oxi::lyser are used to measure COD, TSS, NO3, NH4, pH, O2 and temperature in the inflow and three different effluent streams. The sensors are connected to a con::cube, an operating panel with moni::tool, a software platform, that registers all data in accordance with a time control and makes them available and visible via online access.

With the operator software, moni::tool, relays can be triggered. This function was used to switch four different pumps bringing water from the inflow, effluent of street 1, street 2 and street 3 for 15 minutes each. The water reaches the measurement channel where the sensors are installed, allowing to measure different points with only one set of s::can sensors. After sorting the data it is possible to see correlations between the inflow and the effluent behavior while observing different reactions of the normal activated sludge process and the two hybrid biofilm processes.

The aim of the research project is to use this data to determine ideal process conditions and the maximum capacity of the WWTP with respect to the upgrade option of hybrid biofilm carrier applications. Ultimately, the collected data will be used to calibrate a model in Simba#™ to enable a recalculation of other overloaded plants in Egypt.