A spectro::lyser industrial in the effluent of the mechanical cleaning stage provides continuous and reliable chemical oxygen demand (COD) data for automation and monitoring of the effluent load.

Management of a dairy waste water treatment plant with online COD analysis in Germany

Background

Background

The Wiesehoff Dairy Plant in Schoppingen Germany processes raw milk daily into a range of high quality products. During the refinement process, approx. 500 m3 (130,000 gallons) of waste water are produced every day which is subject to a constantly fluctuating pollution load. The mechanical and biological treatment of the production waste water takes place in a specially constructed waste water treatment plant outside the production site operated by AWS GmbH.

The polluted waste water is pre-treated before being discharged into the municipal waste water treatment plant. AWS GmbH designed each stage of the cleaning process for optimal performance. Among other things, a mechanical pre-treatment by means of dissolved air flotation and an aerobic treatment plant using the sequence batch process were installed. The size of the plant is comparable to a municipal sewage treatment plant with 33,000 population equivalents (PE).

Challenge

Changing inlet loads and volume-proportional dosing of chemicals at the mechanical cleaning stage led to load fluctuations in the downstream aerobic cleaning stage. These load fluctuations led to a considerable deterioration of the sludge parameters in the biological treatment stage.

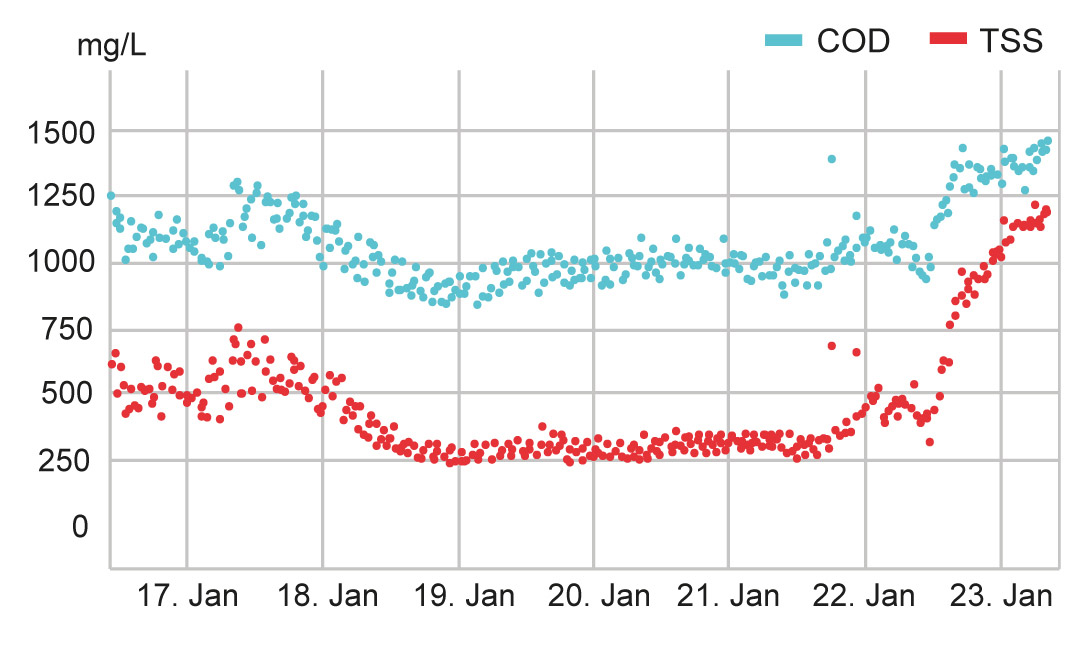

The diagrams show a typical weekly cycle of COD and TSS concentration in the treatment facility. A strong load fluctuation of more than 50 % additional organic load can be clearly seen from 22 to 23 January.

Thanks to the spectrometer probe, it was possible to react directly with a suitable chemical dosage.

s::can’s solution

To react to the load fluctuations, a continuous COD measurement in the effluent of the mechanical cleaning stage was tested using s::can’s spectro::lyser industrial.

The spectro::lyser probe measures the parameters COD, NO3, TSS and Temperature.

During the three month test phase, it was found that the highly fluctuating medium with its various ingredients and compositions required additional adjustment. To further improve the measurement, s::can adapted and implemented a global calibration which was tested and delivered excellent results.

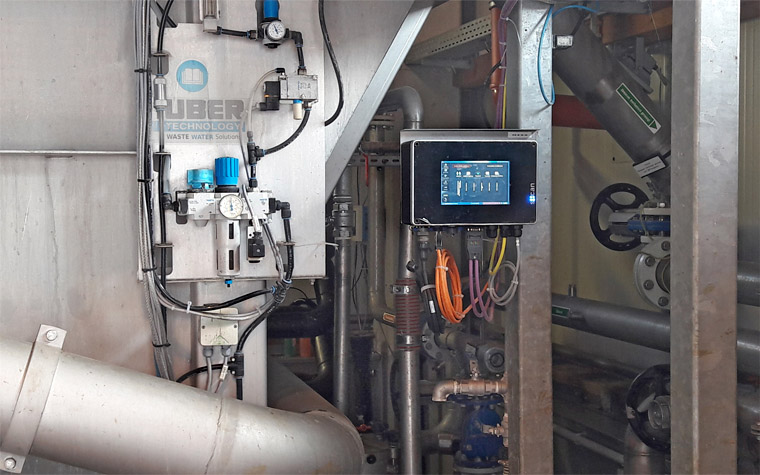

The measurement values are displayed on the con::cube terminal.

The daily fluctuation can be reliably determined, the deviations are minimal. Wiesehoff Dairy Plant is now able to react immediately to load fluctuations in the inlet of the biological cleaning stage. The inlet load to the mechanical and/or biological cleaning stage can now be controlled. In addition, the parameters NO3, TSS and temperature are now continuously monitored with the spectro::lyser industrial which creates additional benefits.