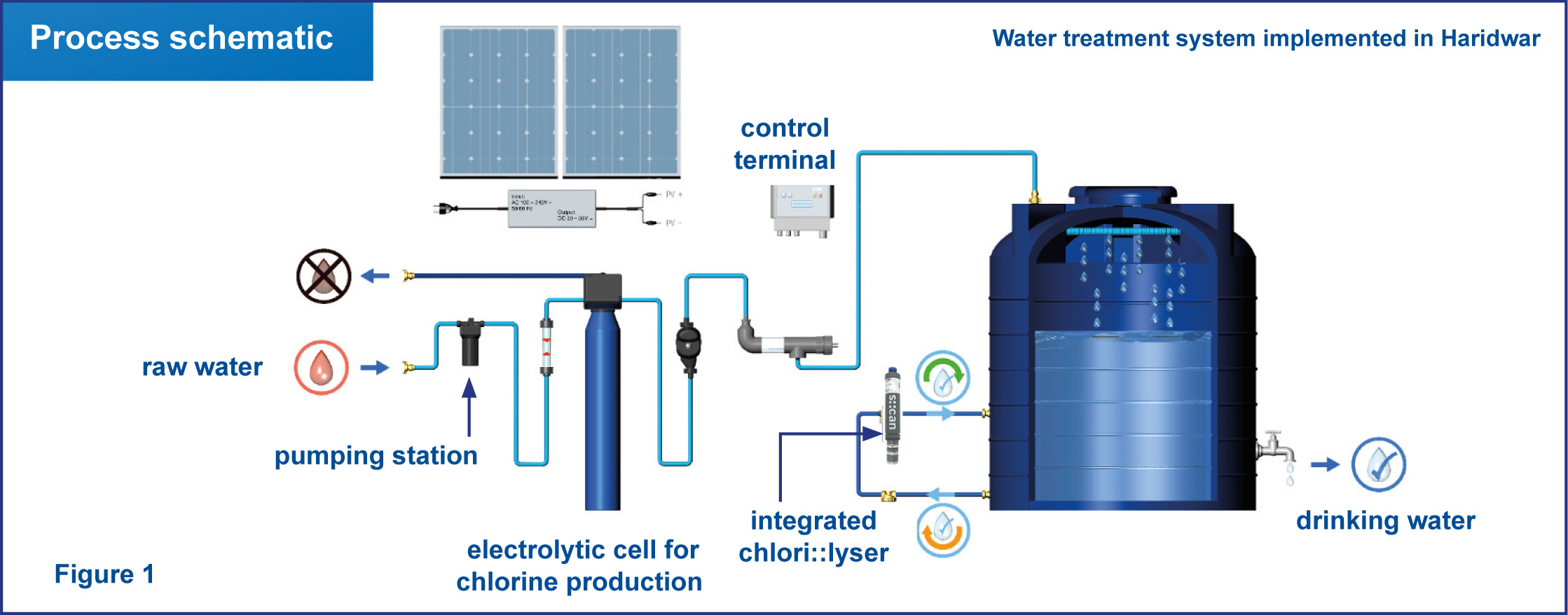

A s::can chlori::lyser is monitoring the residual chlorine concentration of a completely solar driven drinking water disinfection system. The system produces chlorine through inline electro-chlorination using River Bank Filtrate from the Ganga River.

Online controlled in-situ disinfection of bank filtrate for drinking water supply at the Ganga River in India

Background

Background

In Haridwar drinking water is supplied using River Bank Filtrate (RBF) abstracted from wells installed along the Ganga River banks. The bank filtration itself substantially improves the water quality. However, the water still contains a considerable numbers of pathogens. In order to achieve drinking water quality and to assure safe water conditions for distribution and transport, the water needs to be disinfected.

Unfortunately, chlorine is not commonly available and the quantity to be added continuously varies with the changing conditions of the water source. Furthermore, the power supply at the wells is fluctuating and often no electricity is available at all. These challenges have prevented a reliable supply of safe drinking water for Haridwar.

In order to achieve drinking water quality and solve the challenge of chlorine dosing, AUTARCON, the university HTW-Dresden, and the municipal water supply agency Uttarakhand Jal Sanstan (UJS) have implemented a “SuMeWa|SYSTEM”. This drinking water treatment station was developed by AUTARCON and does the following:

1. Pumps water from the well

2. Disinfects the water by producing a small quantity of chlorine in-situ from the natural very low chloride content of the bank filtrate (see figure 1)

3. Safely stores the water for the drinking water supply

4. Monitors water quality and system operation through online sensing

This process does not require any addition of chemicals. The station is completely powered by solar PV energy and thus operates also energetically self-sufficiently and can also be implemented nearly everywhere – all that is required is a freshwater source and sunshine. Maintenance requirements are reduced to a monthly check of the system.

The chlorine production process is controlled online and can be adapted to the given source water conditions. All that was required to do this was an online reading of the free available chlorine content of the water.

s::can’s solution

In order to assure that the correct amount of chlorine is produced, a chlori::yser was integrated into the setting to monitor free available chlorine (FAC). The sensor was installed for a period of three months and the reading frequently confirmed with the DPD1 Method. The reading was further checked by an online ORP sensor. The long term goal is to use the chlori::lyser as an internal control unit for the water treatment system.

The test pilot has proven that the sensor can be reliably applied for the purpose of drinking water quality monitoring and can even serves as a control parameter for the SuMeWa|SYSTEM. The readings have been sufficiently fast and precise for the purpose given here.