The s::can spectro::lyser ensures a complete monitoring of the treated waste water in the brewery’s waste water treatment plant.

The Oettinger brewery in Germany continuously monitors its industrial waste water with s::can

Background

Background

With a total output of 245.7 million gallons per year, the Oettinger group is one of the biggest brewery companies in Germany. Each year, about 2 billion bottles and cans are filled with beer, mixed beers and soft drinks. The family-owned business was founded in 1731. Its headquarters are located in Oettingen, and 1 050 employees work there. Approximately 92.5 million gallons of beer and mixed beer beverages are produced annually at the headquarters production site. This makes the brewery one of the largest brewery locations in Germany. Waste water accumulates through the production of beer and cleaning bottles, which needs to be treated in their own waste water treatment plant.

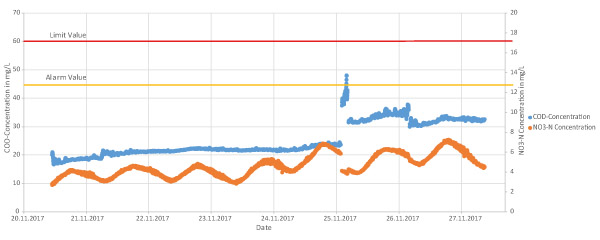

The diagram shows the COD and NO3-N concentrations for one week. On November 25, there was an alarm event.

Challenge

With increased production, waste water has also accumulated. Hence, a WWTP was built in 1992 to relieve the municipal WWTP. From 1992 to 2009, the amount of waste water that had to be cleaned, rose from 1 200 m3/d to 2 700 m3/d, which corresponds to approximately 30 000/99 000 inhabitant equivalents. In addition, the upper legal limit for COD was decreased from 120 mg/l to <60 mg/l.

In order to comply with the maximum amounts and to be allowed to discharge the treated waste water directly into the river, the brewery had to install a continuous monitoring system in their waste water effluent.

s::can’s solution

The only solution to control treated waste water over a long period of time was to send daily mixed and random samples to an accredited laboratory. In 2004, the Oettinger brewery opted for a more sustainable system. A real-time monitoring system was implemented using s::can’s spectro::lyser, which enables them to react on unusual discharges and limit value exceedances.

Benefits

Readings are available in real-time with the automated measuring spectrometer probe. A 1-minute measuring interval is set and an automatic compressed air cleaning system is used to keep the optical measuring element of the probe clean. The availability of the measured values was over 99% last year. Due to the online monitoring of the measurements and an early warning system, the personnel efforts and costs for external laboratories were cut significantly.

Related Posts

-

Achieving operational excellence –

How the pipe::scan transformed water quality monitoring Union Water Supply System (UWSS), an Ontario Clean Water Agency managed facility, is responsible for servicing 66,800 residents in the…

Union Water Supply System (UWSS), an Ontario Clean Water Agency managed facility, is responsible for servicing 66,800 residents in the… -

The Application Process

February 2023 I Today we’ll take a closer look at our application process and give you a few tips on…

February 2023 I Today we’ll take a closer look at our application process and give you a few tips on… -

New generation of s::can monitoring stations V200

November 2022 I Due to operational experience s::can put in place several small technical improvements into the design of s::can…

November 2022 I Due to operational experience s::can put in place several small technical improvements into the design of s::can…